Port Road condition monitoring

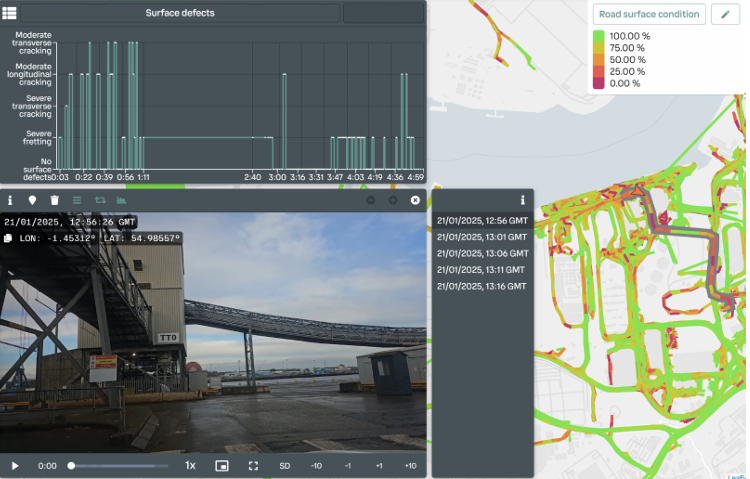

Five Port of Tyne vehicles have had a 5G smart device with an integrated camera installed which will enable continual scanning of the roads, using app and camera-based AI technology to provide auditable reports of port infrastructure.

What is the problem to be solved?

Currently the monitoring of the condition of roads on the Port estate is done by manually by the Estates Maintenance team. The results of the inspec on are documented on a plan of the Port and defects noted are graded. This plan is then scanned and added into the Maintenance system. The key challenge is to automate this process, improving accuracy and productivity for road condition monitoring across the Port of Tyne estate. Specifically, there is a need to

• Reduce manual inspec on me

• Reduce damage to vehicles

• Improve opera onal efficiency ultimately, it is about Port of Tyne being able to efficiently audit their estate and ensure that at all mes infrastructure remains opmally maintained.

What is the solution to the problem?

5G Network Expansion: The network expansion was to provide private 5G coverage across International Passenger Terminal operating areas and connection back to existing 5G network, to enable Port assets to move between sites and con nuously be connected to Port systems. This will also enable future location and operational specific use cases.

This infrastructure was delivered in partnership with Ericsson and has a backhaul connec on to the Port’s existing private 5G network on the South side of the river. N77 radios and baseband provide the network coverage and there is a 10gbps backhaul link to connect the new kit to the existing core. In the short term, the new network will enable the infrastructure scanning use case which is based on AI and cloud processing of the images. Longer term, the North side network will support further use cases and development related to ferry and cruise operations which includes passengers, vehicles and RoRo freight.

Commercial model (Business Case)

The business case for automated road condition monitoring rests on improving operational efficiency of the port and reducing damage to port vehicles. It is anticipated that the smart devices and software platform will provide continuous monitoring and highlight any serious defects and over time, more timely repairs will be carried out when defects are minor (and therefore cheaper). If the internal road infrastructure is maintained to a high standard, this will reduce wear and tear on vehicles, improve operational efficiency if vehicles have less damage or don’t need to slow down for potholes and promote safety for vehicles and pedestrians whilst on-site.

Benefits

Productivity & operational efficiency: Currently the Port carries out a manual inspection of the Port estate quarterly. This takes 2 Engineers 2 full days and totals 32hrs. They carry out minor repairs but anything that is of significant size (>0.5m) is passed to the Infrastructure team who arrange a contractor to carry out an annual repair. The key benefit of this use case is the saving of 32hrs quarterly on this inspection by automa>ng it and having AI flag the problem areas. The Port will then undertake more regular minor repairs to maintain the condition of the road. As minor pot holes won't be left to deteriorate, the Port expects the overall repair cost to reduce, as well as having good quality surfaces which are less likely to damage vehicles. There may be an addi>onal benefit in plant moving across the site quicker if the roads are in good condition.

Lessons Learnt

- Do: Where procurement of subcontractors and contractors is involved, pre-emptive drafting of procurement specifications is beneficial to mely project progression

- Do: Early discussions around resource requirements would have improved processes and shorten timescales

- Do: Commence process of supplier induc on early to ensure approvals are in place in me to carry out onsite work

- Do: 5G network planning - review proposed locations of radio masts alongside ducting maps to ensure appropriate connectivity to utilities

- Do: All parties needed to work together and build in additional me to work through the interoperability issues, as there have been challenges connecting agreed devices to the private network.

- Do: Explore opportuni es to collaborate with wider sectors and other companies within the supply chain i.e. Plant & equipment OEMs looking to innovate on 5G networks

- Don’t: Underestimate the me and complexity to installing or upgrading a 5G network. 5G network upgrade can take longer than initially anticipated

- Don’t: Underestimate the complexity of matching device technology to appropriate vehicles, which has presented problems requiring vehicle subs tu on/modifica on and network upgrade

If you’re ready to embark on a connectivity project, we can point you to the suppliers with expertise in your sector.