Find out how advanced network solutions can help with Connected Worker scenarios to make employees safer, smarter and more effective.

This Photo is licenced under CC BY-SA

What is the problem to be solved?

In the manufacturing sector, particularly when executing complex or hazardous tasks, employees face significant challenges that Connected Worker solutions aim to address. These can include:

- Helping to maintain health & safety standards, which could be significantly enhanced through real-time health and performance monitoring technologies.

- Allowing remote training and assistance for new or inexperienced workers

- Increasing the quality of worker output through a reduction in errors and misinformation

- Continuous improvement through constant collection of objective and subjective in-process data

- Increased worker job satisfaction through gamification and empowerment

What is the solution to the problem?

Within manufacturing, Connected and Augmented Worker solutions can revolutionize manual tasks, by enhancing efficiency, safety, and training. Through the integration of 5G-enabled devices and applications from leading tech companies like Nokia, Zebra, and Honeywell, these solutions can offer robust outdoor and indoor coverage, ensuring seamless mobility around a site. The applications of these solutions include:

- The implementation of AI for visual inspections, which checks if a step in the manufacturing process has been completed correctly and can prompt a worker to check or rework the step if required.

- Digital instruction sheets that provide live task lists, allowing workers to receive comprehensive instructions and record their progress in real-time. This allows both for automatic display and sign-off of instructions, as well as ensuring all workers are using the most up-to-date version.

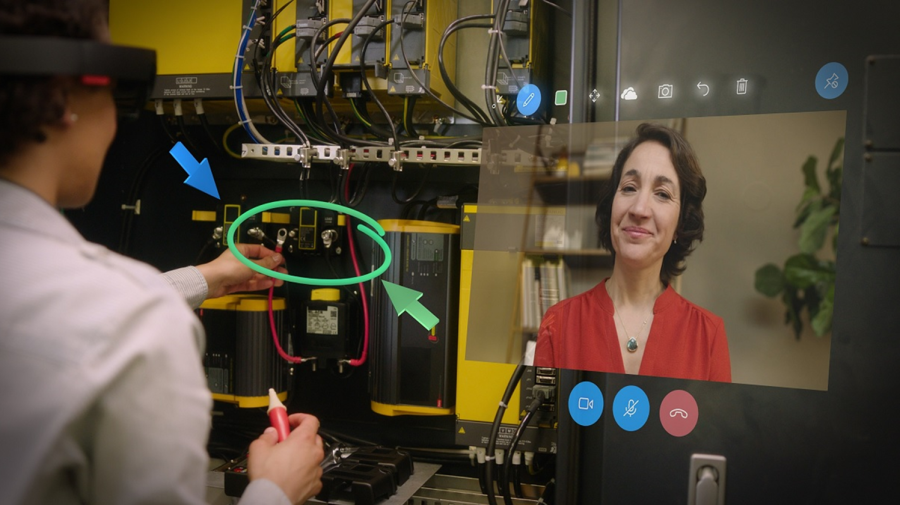

- For situations requiring further assistance, a more experienced technician can be available through instant video calls facilitates on-the-job training and support by connecting the worker with remote experts.

Commercial model (Business Case)

The integration of Connected Worker solutions in manufacturing can lead to strong returns when applied across a wide range of use cases that can improve health & safety and operational efficiency and reduce defects and wastage. These technologies, which depend strongly on the transformation from paper to a fully digital workflow, remote assistance, and improved quality control, can contribute to a reduction in operational costs and improved profit margins through:

- Reducing accidents and QHSE violations

- Less material wastage and rework

- Improved worker efficiency

- Potentially allowing a lower skilled worker to perform the same task

- A reduction in travel between sites

The estimated market for connected and augmented worker solutions is expansive, with procurement considerations that emphasize full data ownership and protection, thus safeguarding sensitive information from competitors and third-party platforms. Funding options are diverse, with most of the pre-requisite hardware and software available as CAPEX or OPEX spending profiles. The size of investment often means that returns are in the 5 – 10 year period, but quickly snowball once the base technology and ways or working are in place.

Benefits

Connected and Augmented Worker solutions can drive significant efficiency, safety, and sustainability benefits for adopters. These advanced technologies, including Artificial Intelligence (AI), enable a more efficient allocation of expert support staff, leading to an environment where expertise is leveraged across an organisation without geographical constraints. This not only enhances workforce mobility but also provides rapid access to critical data and decision-making processes. Moreover, the implementation of remote monitoring can significantly improve worker safety, ensuring compliance with regulations while reducing the risk of claims against a business.

Financially, the adoption of connected and augmented worker solutions can offer a strong value proposition. By streamlining manufacturing connectivity and enabling remote operation, businesses can tap into part-time and remote working opportunities, reducing overheads and increasing the talent pool. They can also contribute to energy efficiency and Net Zero efforts by optimizing worker efficiency and reducing waste. Early adopters can benefit further by commercializing these technologies, potentially offering an additional revenue stream by selling the solution to other companies. Beyond these tangible benefits, such solutions make training more appealing to the new generation of workers, ensuring the industry remains competitive and innovative.

Lessons Learnt

There are several things to be aware of when implementing Connected Worker solutions within manufacturing environments:

- An increase in the number of deployed devices can lead to the loss of localized data if they are not backed up, emphasizing the need for robust data management and recovery strategies.

- Careful network configuration is also vital, as these solutions often require equal upload and download speeds, something that many wireless networks do not implement by default.

- Not fully engaging with an organisation’s IT department can lead to “shadow IT” where engineering / operations run their own equipment that should be (but is not!) maintained and supported by the main IT department.

- They often require internet access to be deployed across an entire site, which needs to be carefully planned out and decisions on 5G vs WiFi (or a hybrid) need to be made.

If you’re ready to embark on a connectivity project, we can point you to the suppliers with expertise in your sector.