Global production of aquatic animals was estimated at 178 million tonnes in 2020, up more than 80 per cent from 1990 levels. The United Nations Food and Agriculture Organization (UN FAO) has called for a “Blue Transformation”, expanding the contribution of fish, seafood and seaweed to food security and nutrition.

The growth and expansion of technologies have enabled fish farms to transform and play this integral role, becoming increasingly efficient by introducing tools to control feed timings and monitor health and growth rate as well as water quality. A strong connection is required, though, something that is not often possible for farms in remote locations.

Could advanced satellite technology change that? “Combining advanced satellite communication technology with advanced analytics provides insights for industries to manage their operations in a much more efficient way,” said Allan Cannon, chief executive of Krucial, at the 9th World Ocean Summit.

These new technologies will also enable salmon farms to move farther out to sea. “There’s a trend towards establishing farms up to 6km off the coast, where salmon farming has a reduced impact on the environment—but you can’t run a fibre connection from the coast out to a farm 6km off the coast,” added Mr Cannon, whose company provides data services in locations lacking traditional communications infrastructure. “Satellites really can help the industry do that.”

Read more below on aquaculture applications.

Real-time monitoring of water environments for smart farm management

IoT in aquaculture helps farmers nurture biodiversity and optimise the environment in which their produce grows. From collecting weather data, water temperature and oxygenation levels to pH levels, salinity, turbidity, nitrate and pollutant levels, sensors and drones equipped with high-definition cameras empower farmers to operate more efficiently and effectively. IoT in agriculture is not necessarily a new concept. Still, with the addition of advanced connectivity solutions like 5G, the potential grows exponentially: AI and robotics enable precision aquaculture at a level not previously seen. Through a process of observing, measuring and responding to various inter and intra-environment inputs, this technology-enabled approach to farm management allows for more tailored interventions. Real-time environmental adjustments help farmers optimise feeding patterns, minimise impact on the environment and carry out essential repair work to damaged nets that might be hard to identify through human observation.

Against a backdrop of rising costs such as feed and labour, real-time monitoring - and the precision management it enables - helps farmers to flourish in challenging times, boosting productivity and profitability.

Scottish Sea Farms worked with 5G RuralFirst to deploy 5 G-connected sensors on their salmon farm off the coast of Orkney. The sensors measured water temperature, oxygen and pH levels to ensure actions can then be taken to adjust activities such as feeding as parameters change. Salmon are cold-blooded so water temperature impacts their metabolism, meaning when temperatures drop the fish will require less feed.

Critically, as the farm is based in the notoriously dangerous North Sea, the data can be accessed at their office for days when the weather is too bad for workers to get out to the pens.

In the 5G RuralDorset project Wessex Internet worked with the University of Exeter and JET Engineering to develop a solution which enables farmers to see what is going on under the water. Excitingly, the project was able to deliver continual video streaming over 5G from underwater. The University of Exeter then used this data and AI to measure biofouling levels on seaweed crops. Being able to understand this information helped the farmer understand and manage the health of their farm ecosystem now and into the future.

In partnership with Scoot Science, Grieg Seafood is using on-farm ocean sensors to collect information on changing ocean conditions (temperature, salinity and oxygen, among others) to help predict ocean trends. The data is supporting Grieg with farm management approaches to reduce exposure to marine risks, plankton blooms and sea lice outbreaks. It is also being shared with other stakeholders, such as scientists and universities, as part of a broader effort to better understand ecological systems.

Tassal, Australia’s largest salmon producer, has installed underwater sensors at its sites which collect data on the environment their salmon live in. This technology is helping Tassal move away from manual reporting to more efficient, timely and accurate data collection. Similarly, Yalelo is a tilapia fish farm in Africa that uses sensors to measure dissolved oxygen levels in cages and ponds. This information helps them to optimise fish feeding and control aeration.

The Umitron PULSE product tracks weather, surface temperature dissolved oxygen, wave height, wind and more. Using satellite data it can provide localised and highly accurate 48-hour weather forecasts and track performance against long-term data, enabling visualisation of trends.

“Being able to visualise a wide area rather than a single point for important parameters such as chlorophyll and wave height is extremely useful for understanding our farm site’s environment more deeply.”

HYODO, Suisan

Rika Sensor provides weather and environmental monitoring solutions across the globe to large fish farms, oyster beds and mussel farms. Their aquaculture monitoring system continuously monitors water quality sensors such as water conductivity, dissolved oxygen, turbidity and pH to improve feed ratios, minimise fish stress, and reduce fish disease and mortality.

Real-time monitoring of species for smart farm management

Whether salmon or seaweed, produce can also be monitored in real-time, allowing for precision management. With advanced connectivity and the technologies it enables, such as automation, robotics and AI, farmers can identify parasites, diseases, growth and the best time to harvest. Connectivity solutions such as 5G offer both high bandwidth, allowing for huge amounts of data to be transferred; and low latency, meaning data is transferred in near real-time for time-critical and high-precision interventions such as introducing cleaner fish into a specific pen or adapting feeding regimes.

A report by Scotland’s Fish Health Inspectorate found that deaths on Scottish fish farms almost doubled in 2022 compared with the year before, to 15m. Critically, therefore, farmers can use these technologies to predict and identify potential risk factors. From IoT sensors to autonomous drones and machine vision, farmers have access to a level of insight into each fish or plant’s colour and growth at a level that would never be possible through human observation. This facilitates faster, more tailored corrective action, resulting in improved animal welfare, higher yields and increased profitability.

Using underwater sensors and even live video feeds can provide not only constant monitoring but extremely precise, granular data, capturing everything from size to growth, swimming rate and even heart rate and metabolism of fish. Such information can be used to determine the hunger status of fish with feeding patterns and then adapt accordingly. The result is a tailored feeding regime that reduces waste, significant when feed costs make up nearly 60% of the total cost invested in fish farming. This has direct implications for yields too: overfeeding can lower the water quality, reduce growth rates and even increase morbidity rates. Under-feeding can decrease muscle conversion and in extreme cases (such as shrimps) can lead to cannibalism and mutual attack.

Scottish Sea Farms worked with the 5G RuralFirst project to connect their salmon farm off the coast of Orkney to a 5G network. Live underwater video feeds enable workers to monitor the 35,000 salmon in each of their 20 cages in real-time, from anywhere in the world. This enables them to monitor that automated feeding has been successfully deployed and identify potential issues with the health of the fish.

Natura Fish is a 19-hectare property in the Algarve, Portugal. It can produce 500 tons of seabass and seabream annually in natural salt-water ponds, which are part of the estuary ecosystem. The farm uses a data platform and sensors from Sensaway that enable them to create a digital twin of their farm to closely oversee their entire operation. Tassal, Australia’s largest salmon producer, has installed underwater sensors at its sites which collect data on their salmon. This technology is helping Tassal move away from manual reporting to more efficient, timely and accurate data collection. Critically, the sensors provide them with constant access to real-time data, providing a much richer set than can ever be achieved with human workers alone.

An Indonesian aquaculture intelligence company known as ‘eFishery’ has developed an AI feed dispenser which helps farmers administer the right amount of feed at the right time. Using sensors to detect the appetite of the animal can reduce the cost of feed by about 21%. In Singapore and Japan, Umitron Cell produces a data-driven smart fish feeder that assists farmers in optimising feeding schedules. These AI feeding devices help reduce feeding costs and maintain water quality.

Vision-based sensors can collate data that using AI, makes it possible to analyse swimming patterns, size, and injuries on the fish and compare with historical data to identify anomalies and trends. Xpertsea offers an AI device called Xpercount which applies machine learning to camera feeds to weigh, count, image and size shrimp in seconds. These collected data are analysed for detecting the periodic health of the stock.

Cermaq has developed its iFarm solution that uses machine vision and AI to scan each fish, recording and tracking its health profile (weight, lice counts, wounds, signs of illness etc) so the farmer can adapt health plans accordingly and treat each fish. The solutions can be used for Atlantic salmon, rainbow trout, European sea bass, and gilthead sea bream.

AquaCloud is a big data project, part of Norway’s NCE Seafood Innovation cluster. The initial scope of the project was to establish a secure database for storing data and use advanced analytics to identify where sea lice outbreaks were probable. This reduced fish mortality and minimised dependency on more expensive treatments.

Staying in Norway, Manolin has created an aquaculture welfare platform that enables fish farmers to monitor fish behaviour and health, with the ultimate aim of reducing mortality rates. Their predictive fish health monitoring system uses sensor data and AI to provide real-time fish data that can be compared against industry benchmarks and highlights risk factors, enabling disease forecasts.

The ability to find lab results, environmental information, and farm data in one place has great potential to improve our production. With this, our team can optimise efficiency, more accurately assess risk, and improve our fish welfare."

Andreas Skagøy, Fish Health Manager at Måsøval Fiskeoppdrett

And it’s not just fish that can be monitored in real-time. The 5G RuralDorset project delivered 5G connectivity to Jurassic Sea Farms, a seaweed farm in Portland Port. They connected rugged sensors as well as providing a live underwater video stream. The data provides the farm with a better understanding of seaweed growth and biofouling, enabling them to strike the right balance between seaweed quality and quantity and optimise harvest scheduling.

Automation of husbandry

Labour and skills shortages pose a major challenge for the aquaculture industry, with the locations of fish farms cited as a major contributing factor for failing to attract young workers into the sector. According to the FAO, the production of aquatic animals directly used for human consumption reached 157 million tonnes in 2020, the second highest on record. With the increasing reliance on farmed fish to meet growing global food news, aquatic food production is forecast to increase by a further 15 % by 2030, further exacerbating the lack of qualified labour.

The case for embracing automation is clear. When it comes to aquaculture, there are significant benefits to increasing the efficiency of operations. For instance, ensuring produce receives the right amount of feed at the right time, can result in better growth rates and higher yields. At the same time, consistent care, less stress-inducing human interaction and earlier detection of biohazards can improve welfare. Additionally, robots can conduct tasks continuously in any weather conditions, removing human workers from hazardous scenarios.

Automation in aquaculture can be deployed at various stages, from feeding to measuring and cleaning ponds and nets. Advanced connectivity can play a critical role in enabling this technology, ensuring data is collected and transferred in real-time that can prompt automated systems and, where necessary, human intervention.

Automated feeders in fish pens can help to minimise wastage, dispensing feed automatically based on real-time data feeds on water temperature and other influencing factors. More than 60% of feeding material eventually turns into toxic compounds that can reduce water quality, meaning automated feeding tools can reduce operating costs, waste and environmental impact. Such tools include both automated dispatchers and, in large culturing environments, drones.

Scottish Sea Farms have deployed 5G connected water temperature, oxygen and pH sensors which are helping them to identify the right time and volume to feed their salmon. The farm off the coast of Orkney is frequently subject to hazardous weather conditions so the ability to both access this data remotely and then trigger automated feeding systems.

An Indonesian aquaculture intelligence company known as ‘eFishery’ has developed an AI feed dispenser which helps farmers administer the right amount of feed at the right time. Using sensors to detect the appetite of the animal can reduce the cost of feed by about 21%. In Singapore and Japan, Umitron Cell produces a data-driven smart fish feeder that assists farmers in optimising feeding schedules. These AI-powered automated feeding devices help reduce feeding costs and maintain water quality.

Stress in fish can impact growth rate and even result in fatality. Automated monitoring reduces direct fish-human interaction and can therefore reduce stress as well as avoid exposure to disease. Live underwater video feeds enable farmers to monitor fish remotely while image processing has been used to successfully predict fish weights, improving the growth rate of fish by up to 47%.

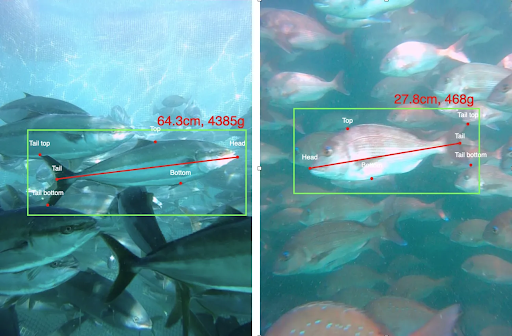

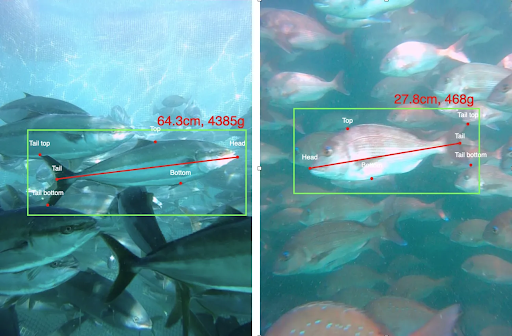

Umitron has developed a fish body measurement system that reduces stress for fish but also provides far more accurate data. Instead of manual approaches which rely on taking averages from a small sample of fish. This automated system utilises small underwater cameras and a unique AI algorithm to achieve high body measurement accuracy at an individual fish level.

Image

Many research institutes and companies, including Robotfish, Cermaq, Innovasea, SINTEF, SeaVax, Sublue and MIT’s AUV lab have developed and are developing various types of robots for aquaculture. These robots are capable of conducting a variety of tasks including underwater robots that can inspect and repair nets, remove sick fish and even vaccinate fish. Automating vaccination can be of particular value, as it’s a laborious and time-consuming procedure, especially for flatfish, with low accuracy. Plus the necessary handling of the fish creates a high risk of contamination. Several machines are now available that can vaccinate between 7,000 and 9,000 fish an hour, but they require fish to be of similar size and larger than those for manual injection. Research trials in Korea have successfully developed accurate vaccinating robots specifically for flatfish that are capable of achieving an average injection rate of 2,000 per hour.

AI for rapid and precise decision-making

With advanced connectivity, the volume of data that can be collected and transferred to fish farmers in near real-time is vast. However, the data is only valuable if it can be analysed and turned into meaningful insights.

AI has the power to transform the sector, making aquaculture a more data-driven and less labour-intensive field. Able to process data from sensors, cameras and drones, AI can deliver insights in near real-time. The technology can help streamline all aspects of operations: leveraging AI algorithms allows for invaluable insights into everything from fish growth patterns to feeding behaviours as well as detecting and predicting anomalies and risks.

Granting fish farmers complete real-time control over production systems will save time and cost, reduce input costs and losses, ensure the welfare of fish, and optimise yields and profitability.

One of the main applications of AI in aquaculture is processing the data collected from smart monitoring systems that continuously collect real-time data on water quality, temperature, oxygen levels, fish behaviour and more. AI algorithms analyse this data to identify any deviation from optimal conditions and provide timely alerts to farmers, allowing them to take appropriate actions such as adjusting feeding schedules, modifying water parameters, or administering treatments as needed. AI-based models can assist in optimising feed management and reducing wastage: by analysing historical data on fish growth and feed consumption, machine learning algorithms can determine the most efficient feed formulation and feeding regimes, leading to improved growth rates while also minimising environmental impact.

Feed costs make up nearly 60% of the total cost invested in fish farming and optimising feeding can have a significant impact on yields. Under-feeding can decrease muscle conversion and in extreme cases (such as shrimps) can lead to cannibalism and mutual attack. Over-feeding however, causes feed wastage and depletes the water quality. AI can be used to measure appetite levels and ensure the right amount of feed is given at the right time. An Indonesian aquaculture intelligence company known as ‘eFishery’ has developed an AI feed dispenser which does exactly this. Using sensors to detect the appetite of the animal can reduce the cost of feed by about 21%. In Singapore and Japan, Umitron produces a data-driven smart fish feeder that assists farmers in optimising feeding schedules. These AI feeding devices help reduce feeding costs and maintain water quality. The aquaculture start-up has also developed a Fish Appetite Index, the world’s first real-time ocean-based fish appetite detection system. It uses advanced machine learning algorithms to analyse video data collected directly from farm sites to calculate fish appetite. This allows farmers to make data-driven decisions when feeding their fish.

Vision-based sensors on AI devices make it possible to analyse swimming patterns, size, and injuries in the fish and compare them with historical data to identify anomalies and trends. Xpertsea offers an AI device called Xpercount which applies machine learning to camera feeds to weigh, count, image and size shrimp in seconds. These collected data are analysed for detecting the periodic health of the stock.

Early disease identification and prevention is another significant aspect of AI in fish farming. Using image analysis and pattern recognition, AI algorithms can identify early signs of diseases, parasites, or abnormalities in fish appearance and behaviour. This enables prompt diagnosis and targeted treatment, reducing the need for excessive use of antibiotics and chemicals while improving fish welfare. They can even detect outbreaks before they happen by comparing live data with historical or programmed data.

AquaCloud is a big data project, part of Norway’s NCE Seafood Innovation cluster. The initial scope of the project was to establish a secure database for storing data and use advanced analytics to identify where sea lice outbreaks were probable. This reduced fish mortality and minimised dependency on more expensive treatments.

Aquaconnect, an Indian aquaculture technology start-up, has created a mobile application called ‘FarmMOJO’ that helps shrimp farmers analyse water quality and predict diseases. Through these applications, farmers can prevent diseases even before the outbreak starts. Periodically, pictures of shrimp diseases and parasites are uploaded into the app by the farmers and the developers so the AI can continuously learn.

AR/VR to improve operational efficiencies

Aquaculture is a highly variable and laborious sector: there are significant variations between different species, conditions are subject to changing weather conditions and farms are increasingly being moved further offshore making it more challenging to access support in a timely fashion. When margins are tight, finding ways to improve operational efficiencies and minimise downtime are critical to long-term success.

Augmented (where computer-generated images are superimposed over a view of the real world) and virtual reality (a 3D computer-generated simulation of a real-world environment) can support fish farmers in a variety of ways and when powered by the high bandwidth and low latency of advanced connectivity solutions such as 5G, can enable real-time remote support and collaboration over ultra-high-definition video.

With the assistance of AR, farmers can gain a better insight into production environments in a more cost and time-effective manner, as well as reducing risks to human workers. It can be used for instance to facilitate underwater drone and robot operations, including monitoring fish behaviour and identifying net holes and dead fish. AR has been used to increase the efficiency of field production, monitor and analyse mortalities, and health status and measure water parameters.

It can also be an effective tool for teaching and education around the industry. The Norwegian University of Science and Technology (NUST) has developed and applied AR and virtual reality (VR) to teach students about fish welfare, disease prevention, escaping fish and dangerous working conditions. Such tools can also be used to facilitate more effective remote collaboration and assistance, for example between different fish farm locations, reducing the need to travel or send out experts when there is a problem.

Predictive maintenance of machinery

With profit margins being squeezed, now more than ever farmers need to increase or at least maintain their outputs. One way to support this is by reducing downtime, especially for critical machinery such as feeding robots. As aquaculture embraces the move to automation, the need to improve performance, minimise downtime and extend the lifetime of machinery will become even more vital.

Computer vision and sensors attached to equipment can feed AI models to allow for predictive maintenance, and the identification of early indicators of wear, tear or malfunction. Advanced connectivity, such as 5G, facilitates the processing of data in real-time. These insights, combined with analysis of vibrations, temperature and oil usage, create a predictive maintenance model, which results in detections up to 90 days in advance. Scheduling and controlling maintenance and repairs this way minimises downtime, which extends the lifespan of machinery and reduces wastage from time-based maintenance approaches.

As a part of the Worcestershire 5G project, manufacturer Mazak successfully deployed automated remote predictive maintenance, taking advantage of 5G’s ability to process large amounts of data. The factory is now able to provide real-time analysis of machine status and feed this information to a cloud system. The company’s spindles are usually only removed for corrective maintenance after an issue or failure occurs but with the arrival of 5G, early warning signs of damage are available; this reduces repair costs, as well as downtime.

The Port of Felixstowe used 5G IoT devices and predictive data analytics to reduce unscheduled downtime of its 31 quay-side and 82-yard cranes. AI optimises the crane’s predictive maintenance cycle, which improves performance and the productivity of ship-to-shore operations.

These examples, though from other sectors, clearly demonstrate the important role connectivity can play in digitising the maintenance process, facilitating early detection of faults and minimising downtime. This can have a significant impact on the bottom line, which is particularly relevant for the farming industry where costs are spiralling.

Real-time monitoring of weather conditions

Weather conditions have a significant impact on aquaculture. Drought can cause serious problems, especially at facilities depending upon surface sources of freshwater. Ponds filled by overland flow (storm runoff) may decrease greatly in volume, which crowds the culture animals into less volume, and concentrates potentially toxic metabolites.

Climate change is bringing more unpredictable weather and having a significant impact on sea temperatures, currents, wind, ocean acidification and air temperature. Since March 2023, Scotland's waters have been gripped by an unprecedented Category four marine heatwave, causing mass marine mortalities. Some of Scotland's salmon farms have seen as much as a five-degree sea temperature increase, leading to a proliferation of sea lice infestations.

And this impacts not just aquatic products but also human workers. Storms are predicted to increase in frequency and intensity in the UK and with concerns about the impact on coastal ecosystems pushing fish farms further out to sea, workers can find themselves at tangible risk if they’re caught out in severe weather.

Connected weather and environmental sensors and AI can help detect, analyse and even predict weather events at a hyper-local level. Workers can track temperatures, wind speed and direction, temperature, rainfall, oxygen levels, and solar radiation, as well as identify patterns and predict the weather, enabling them to respond faster to changing conditions and take preventative actions sooner.

The 5G RuralDorset project deployed the first operational 5G data buoys in the UK that measured in-shore wave height and currents for water safety monitoring. Such data is useful for making decisions about whether it’s safe to send workers out to fish pens and to inform general public safety and emergency responses.

The solution, developed by JET Connectivity, is delivered through a 5G mesh communications network that can be deployed in any maritime environment to deliver high bandwidth connectivity to multiple platforms running an array of sensors. This enables workers to have access to real time data including live video feeds around the weather at sea.

Image

Improve worker safety and satisfaction

Many fish farming tasks are acknowledged to be dangerous, not least the fact that aquaculture involves working in or around water, and often working alone and at night which compounds that danger. Hazards associated with offshore aquaculture are akin to those associated with commercial fishing and offshore drilling, while onshore aquaculture has the added issue of hazards found in agriculture.

In addition to direct injury threats to workers, there are additional risks to health from working in the heat or cold, dehydration, work-related neck and upper-limb disorders, respiratory problems, allergies, parasites, bacteria from feed, skin issues, and hazards related to ingestion and inhalation.

Connectivity, and the technologies it enables, can help to minimise those risks. Real-time weather monitoring with sensors, drones and AI can ensure workers aren’t sent out in dangerous conditions. Robots can be deployed to undertake laborious tasks such as feeding, and cleaning ponds and nets, as well as hazardous tasks such as underwater inspections. The introduction of a more high-tech way of working can also attract fresh talent into the industry and provide more skilled, engaging work.

The 5G RuralDorset project deployed the first operational 5G data buoys in the UK that measured in-shore wave height and currents for water safety monitoring. Such data is useful for making decisions about whether it’s safe to send workers out to fish pens and to inform general public safety and emergency responses.

The solution, developed by JET Connectivity, is delivered through a 5G mesh communications network that can be deployed in any maritime environment to deliver high bandwidth connectivity to multiple platforms running an array of sensors. This enables workers to have access to real time data including live video feeds around the weather at sea.

Scottish Sea Farms was a trialist in the 5G RuralFirst project and had their salmon pens off the shore of Orkney connected via 5G. Various monitoring solutions were deployed including water monitoring and a live video stream of the fish, which enabled a degree of remote monitoring and could help them to make decisions about when to feed the fish without having to send workers out to sea. A significant benefit when you consider the North Sea is one of the most dangerous seas in the world.

Avramar has 71 fish farming sites across Greece and Spain, 12 fish hatcheries and three fish feed production sites. The company has 12 static platforms off the coast of Astakos and worked with G4S on connected solutions to improve worker safety. Every employee wears a life vest and if a person falls into the water, an alarm is triggered which is linked to the G4S monitoring centre, based on the mainland at an Avramar production site, close to Astakos. The tracker has a GPS signal, which can precisely pinpoint where that person is.

Increase security

Aquaculture sites can be susceptible to theft and significant physical damage and as with other areas of agriculture, there is an increase in organised crime activity. Even in cases where the amount of fish stolen is not significant, these activities can damage the equipment, nets and cages used in the farms. While unauthorised access to fish can also increase the spread of disease.

High-definition connected cameras and even drone patrols can help, providing near real-time feeds to workers and alerts of suspicious activity.

Avramar has 71 fish farming sites across Greece and Spain, 12 fish hatcheries and three fish feed production sites. The company has 12 static platforms off the coast of Astakos and found post-COVID that human surveillance was no longer sufficient to ward off poachers.

Working with G4S, they deployed specialised nautical radar and state-of-the-art thermal and optical imaging cameras to protect the perimeter of each farm. Vessels which come too close are detected by radar and the system can distinguish whether a detected boat is either a known “friendly” vessel or an unknown one.

All systems are linked to the monitoring centre and an unidentified vessel will activate loudspeakers and a rotating beacon at the farm. Over the Tannoy, personnel can communicate to the boat’s captain to move away from the farm. If necessary, the G4S speedboat team can attend quickly to the correct location, to ensure the boat doesn’t stray further into the farm.”

Panagiotis Lamprintzis, G4S Greece secure solutions project manager

Magos offers a similar solution for sites situated in the open sea. Built with rigorous hardware their connected camera system withstands waves, spray and fog witha field-proven mean time between failure (MTBF) of over 50,000 hours (>5 years) in sea-side installations. The solution offers early-warning coverage and tracking of threats long before they reach the protected area.

Track product provenance and offer greater visibility into the farming process

Aquaculture is recognised as key to global food security, yet food provenance is becoming increasingly important to retailers and consumers. Unregulated aquaculture can expose consumers to health risks from pathogens, antibiotics and banned chemicals. Species substitution and the exchange of aquaculture produce with wild-caught produce are emerging concerns. To ensure consumer confidence, contain risks and effectively demonstrate adherence to regulations, methods to determine the species, production methods and geographic origin of seafood need to be readily available.

Smart monitoring through sensors, connected cameras and automated equipment can digitally record rich data (including fish health and density of fish in a pen), enabling fish farmers to produce more resilient produce and provide sea-to-fork traceability. This also makes it easier to achieve organic certification.

Scottish Sea Farms worked with the 5G RuralFirst project to deploy 5G connectivity to salmon pens off the coast of Orkney. Their salmon is provided to a premium UK retailer who provides strict requirements around fish density and treatment. Through live monitoring of the oxygen and temperature levels, plus live video feed of the salmon, they can both optimise the salmon’s health and provide clear metrics on the conditions the salmon are kept in.

See what Reuters had to say about it here.

Blockchain is also being used by fish producers to provide immutable records that can be accessed by both producers and retailers. As part of the Norwegian Seafood Trust, Nova Sea uses blockchain to securely record and present data from the fish’s entire life cycle such as what it ate, where it was raised, the water quality of its surrounding environment and the mode of transport from sea to fork. Bakkafrost, a leading producer of salmon in the Faroe Islands, uses blockchain to trace its production through the supply chain. DNA markers for each salmon are recorded, ensuring the salmon is fully traceable, helping to combat food fraud, increasing transparency and providing the information required to obtain sustainability certifications.