Around £22 million worth of fruit and vegetables were wasted because of workforce shortages in the first half of 2022 alone, according to an NFU survey, resulting in significant crop losses at a time when the country is experiencing the worst cost-of-living crisis in generations. This sits against a backdrop of environmental challenges: agriculture is directly responsible for up to 8.5 per cent of all greenhouse gas (GHG) emissions, with Nitrous oxide (N2O) being the most important greenhouse gas (GHG) from a horticultural perspective. Emissions are further increased by crops and processed derivatives being flown, shipped or driven thousands of kilometres before they are sold—and as we know, not always consumed.

Leveraging advanced digital technologies, precision horticulture is based on observing, measuring and responding to temporal and spatial variability. While this approach has advantages for growers, this form of cultivation is also important because it is more sustainable than conventional intensive growing methods. In addition, precision techniques are suitable for high-value horticultural crops, as they can increase economic returns. These modern techniques are expected to reach $15.6 billion by 2030, minimising inputs, labour, and time, maximising productivity and profitability and most importantly, reducing environmental impact.

Read more below on horticulture applications.

Real-time monitoring of environments for smart farm management

IoT in horticulture helps growers improve the fertility of the land, nurture biodiversity and optimise the environment in which their produce grows. From collecting nutrient density information to irrigation levels, lighting, temperature and humidity, sensors empower growers to operate more efficiently and effectively. IoT in agriculture is not necessarily a new concept, but with the addition of advanced connectivity solutions like 5G, the potential grows exponentially: AI and robotics enable precision horticulture at a level not previously seen. Through a process of observing, measuring and responding to various inter and intra-environment inputs, this technology-enabled approach to farm management allows for more tailored interventions. Real-time environmental adjustments help growers to prevent or reduce mould, weeds and other threats, while providing only the fertilisation and irrigation needed to reduce costs and optimise yields.

Against a backdrop of rising costs of key inputs like fertiliser, real-time monitoring - and the precision management it enables - helps growers to flourish in challenging times, boosting productivity and profitability. If 25% of farms adopted precision farming by 2030, yields would increase by up to 300 million tonnes per year claims Bell Labs Consulting.

Real-time monitoring of produce for precision farming

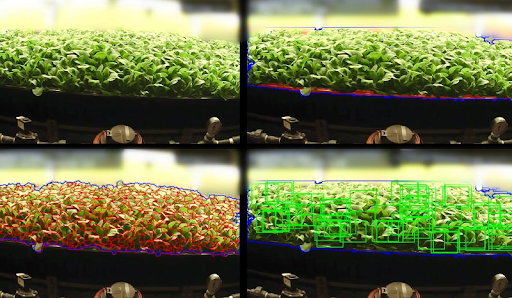

Produce can also be monitored in real time, allowing for per-plant farming. With advanced connectivity and the technologies it enables, such as automation, robotics and AI, growers can identify biohazards, diseases, signs of plant stress and the best time to harvest. Connectivity solutions such as 5G offer both high bandwidth, allowing for huge amounts of data to be transferred; and low latency, meaning data is transferred in near real-time for time-critical and high-precision interventions such as applying insecticide to a particular plant.

Crucially, growers can use these technologies to predict and identify potential risk factors. From IoT sensors to autonomous drones and machine vision, growers have access to a level of insight around each plant’s colour and texture down to a pixel level that would never be possible with human workers. This facilitates faster, more tailored corrective action, resulting in better outcomes, higher yields and increased profitability.

Automation for improved efficiencies

More than 22 million pounds of fruits and vegetables in the UK were wasted in 2022 because of a shortage of workers to pick crops. Labour shortages, exacerbated by Brexit, have accelerated an increase in farmworker wages at a time when growers are facing rising fertiliser costs and grappling with the effects of climate change.

Autonomous farming machinery - including drones and autonomous robots - can offer an immediate solution to the problem. The technology performs precise, targeted and individualised interventions based on connected-sensor GPS and imagery analysis, freeing up workers and driving efficiencies.

Increasing the autonomy of machinery through better connectivity could create $50 billion to $60 billion of additional value by 2030, according to McKinsey.

AI for rapid and precise decision-making

With advanced connectivity, the volume of data that can be collected and transferred to growers in near real-time is vast. However, the data is only valuable if it can be analysed and turned into meaningful insights.

This is where AI comes in. The technology can help growers both identify risks - such as crop disease or damage - and the optimal time to conduct tasks from watering to weeding and even harvesting. Drones using high-quality and AI-powered cameras can tell apart healthy fruit from spoilt crops and weeds. AI analysed sensor data can foresee weather patterns, crop yield, soil nutrients and other factors that directly impact operational efficiency.

Equipping growers with this information ensures quicker action with greater accuracy. Ultimately, this will save time, and cost, optimise crop management and increase yields.

More sustainable operations

The world will need to produce around 70% more food by 2050 to feed an increased world population of 9.7 billion, according to estimates by the UN. Still, 14% of food harvested worldwide is currently lost between harvesting and retail, with inadequate harvesting time, climate conditions and harvesting methods all contributing to on-farm losses. New approaches are desperately needed: alongside waste, the chemicals used in agriculture are directly responsible for up to 8.5% of all greenhouse gas emissions.

Sensors, AI and automated machinery enable precision farming, managing everything from watering to weeding and even harvesting more efficiently and sustainably.

Predictive maintenance of machinery

With profit margins being squeezed, now more than ever growers need to increase or at least maintain their outputs. One way to support this is by reducing downtime, especially for critical machinery such as weeding or harvesting robots. As horticulture embraces the move to automation, the need to improve performance, minimise downtime and extend the lifetime of machinery will become even more vital.

Computer vision and sensors attached to equipment can feed AI models to allow for predictive maintenance, and the identification of early indicators of wear, tear or malfunction. Advanced connectivity, such as 5G, facilitates the processing of data in real time. These insights, combined with analysis of vibrations, temperature and oil usage, create a predictive maintenance model, which results in detections up to 90 days in advance. Scheduling and controlling maintenance and repairs this way minimises downtime, which extends the lifespan of machinery and reduces wastage from time-based maintenance approaches.

Real-time monitoring of weather conditions

Fruit and vegetable production has always been at the mercy of the weather: too much rain, plants become stressed and die; too much heat and plants wither, bolt and die. The impact of climate change is now undeniable, delivering the UK hotter summers, wetter winters, increased likelihood of flooding, and more extreme and unpredictable weather.

This has big implications for growers, with NFU Scotland reporting that floods in Scotland in October 2023 cost growers millions in lost unharvested high-value vegetables such as potatoes, broccoli and turnips. Similarly extreme heat in the summer of 2022 caused fruit and vegetables to die on the vine.

Connected weather and environmental sensors and AI can help detect, analyse and even predict weather events at a hyper-local level. Growers can track temperatures, wind speed and direction, cumulative rainfall, ambient humidity, dew point, soil moisture, humectation and humidification of crops, enabling them to respond faster to changing conditions and take preventative actions sooner.

Automated environments can increase shade and ventilation in response to rain, humidity, wind and temperature to continuously optimise the conditions for produce grown in indoor or covered environments.

Improve worker safety and satisfaction

Agriculture has the worst rate of worker fatal injury, with the annual average rate over the last five years around 20 times as high as the wider industry rate, according to Safety Nation. Working with hazardous machinery poses significant risks but manual activities such as carrying crates of harvested fruit and vegetables can also cause strain and injury. In emergency scenarios, being able to call for help is vital and basic, reliable connectivity is essential.

More advanced connectivity can also support both worker safety and satisfaction. Automation of manual, laborious tasks can both free workers up to engage in more fulfilling work but also potentially remove them from hazardous scenarios i.e. using robots to move full crates of harvested goods.

Security of farming equipment

Farm theft is on the rise. In 2023, NFU Mutual, the UK’s leading rural insurer, released a Rural Crime Report estimating rural crime cost the UK £49.5 million in 2022. Quad and ATV thefts are increasingly common against a backdrop of increasing costs and a low supply of farm machinery globally. Rural theft has become more organised and steadily increased since the pandemic, shooting up by 22% in 2022. As a result, the UK cost of agricultural vehicle theft reported to NFU Mutual soared by 29% to £11.7m in 2022.

Connected technology solutions are here to help. Connected CCTV and drones can provide real-time feeds of farmland, with 5G enabling ultra-high-definition quality. Expensive farm machinery can be fitted with geo-fencing, which triggers an alarm if it goes beyond farm boundaries.

Optimising post-harvest management to reduce waste

More than enough food is available to feed the population of the entire world, yet 14% of food produced never makes it to the consumer, according to the UN Food and Agriculture Organization. This loss, which occurs throughout the production and food supply chain - from harvest up to the retail level - will need to be curbed if the agriculture sector is to successfully feed growing populations while also reducing emissions.

Key causes of on-farm losses include inadequate harvesting time, climatic conditions, harvesting practices and challenges in marketing produce.

Crop waste is one of the factors that contribute to the accumulation of one billion tons of annual agricultural waste.